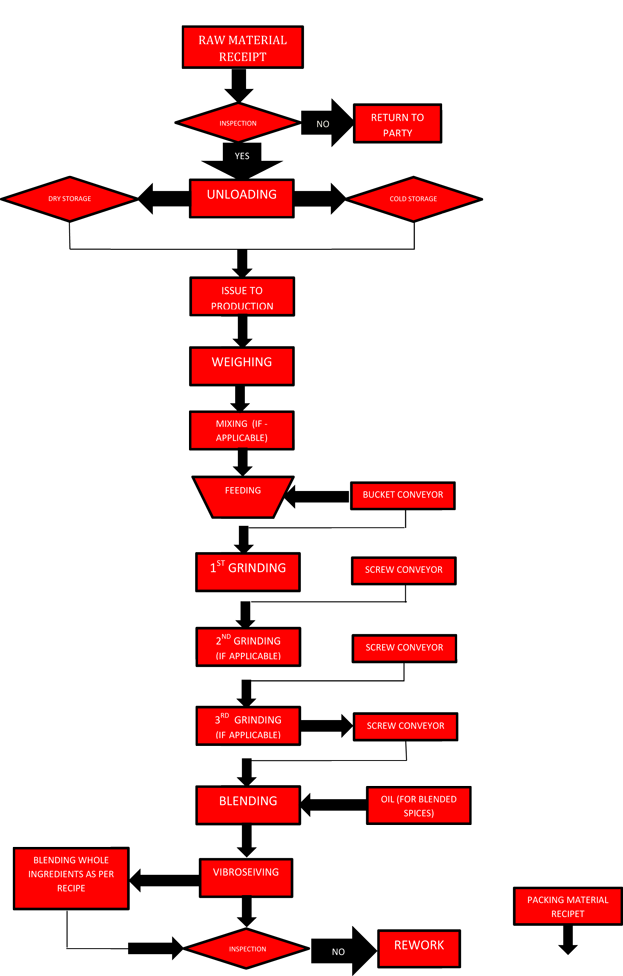

Procurement of Rawmaterial

We purchase the raw material from the local mandis or APMC’s as well as outstation mandi’s. We ensure that the material is sourced from the producing centers during the peak harvest to take advantage of the freshness as well as colour. India is home to several spices and other agri commodities which enables us to gain a competitive edge over our competitors in terms of quality and prices.

Our experienced and efficient staff in the Procurement Department makes sure that only best quality products are sourced from the market, which is inline with the buyer standards and requirements. The desired quality of the products is tested and the final purchase takes place only upon approval from the quality control department.

Fumigation Process

The goods are sent to Fumigation department after carrying out the initial stages of procurement. This ensures that the goods are free from all harmful insects and pests before they enter any further process.

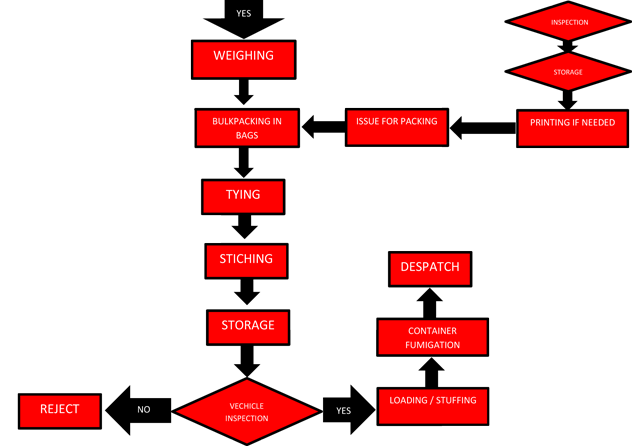

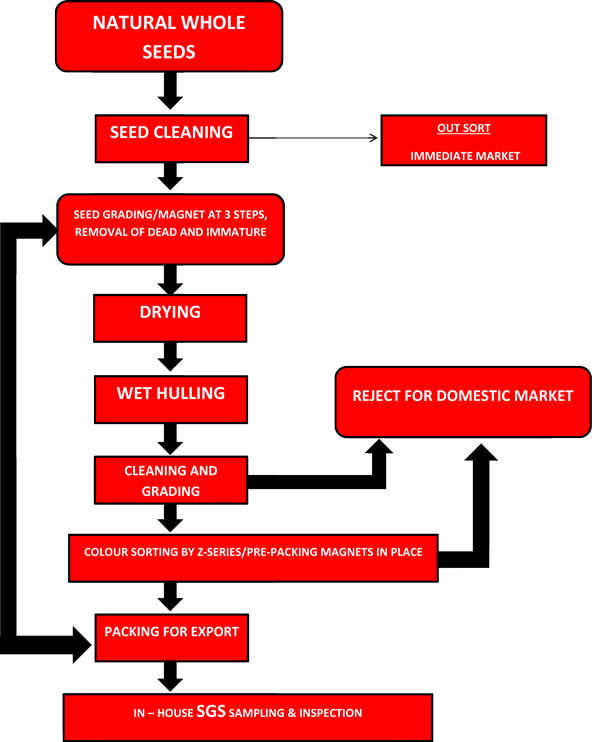

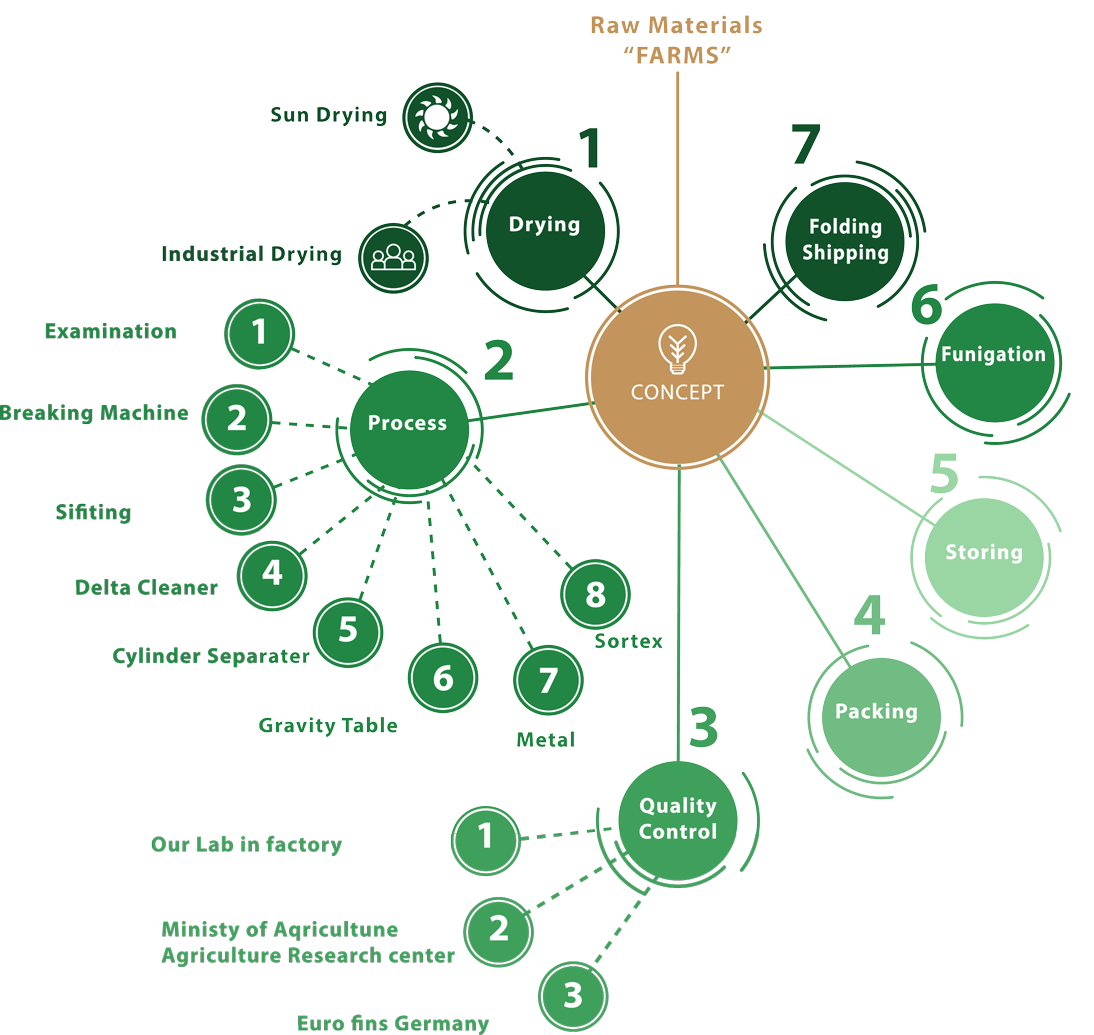

Hightech Cleaning Plant

Seed spice cleaning plants

The preliminary processing of the raw material begins with the pre-cleaning process. Thereafter the raw material is processed in two fully automatic seed spice cleaning plants that provides faster results. It reduces the process time and helps to achieve the schedule set for dispatch of the orders received and ensures quality product delivery to the customer.

De-stoner

After the cleaning process, Distoner plays the function of extricating / Separating the metal trash or any kind of stones in spices, pulses etc. This is done without bringing any harm to the material by means of air and the difference of density between them. It consumes minimal energy and yields maximum returns.

Gravity Separator

The Gravity separator for spices is a part of the process of cleaning of the product to ensure the maintenance of the quality of the product. Its fundamental function is product grading and impurity separation by difference in spice gravity of material that is otherwise of the same size and shape.

Sortex Machine

This engineered to perfection equipment is fully computerized and is useful in maintaining the quality of the product by sorting of the material on their colour basis. It ensures that standard colour is maintained to deliver best quality grade of the product with the assurance of consistent quality. It is highly efficient in removing contaminants of a large variety and is effective in the harshest of environments.

Grinding Plant

We have specialized grinding machines for Chilly, Turmeric, Coriander Cumin Seeds etc, which is grinded under special instructions and procedures.

Chilly Grinding

The chilly procured from the market is in whole form, which is then sorted according to its quality and then send to the laboratory for further testing. After approval from the laboratory, the chilly is cleaned and also hand picked to remove all kinds of waste and dirt.

Turmeric Grinding

Turmeric whole when procured from the market is cleaned and then grinded to obtain the finest quality to satisfy the customer requirements.

Coriander-Cumin Grinding

The Coriander-Cumin Seed undergoes rigorous cleaning procedures to avoid the involvement of minute dust particles and wastes. Only the best quality is send for further grinding so that the final product is pure and of desired quality. We also have special grinding machines for curry powder and to convert other Products in powder form.

Flour Mill

We have specially built in house Flour Mills for Rice Flour, Wheat Flour, Bajri Flour, Besan Flour etc where complete care is maintained to give the consumers the best quality product.

Sterilization

Sterilization of spices is done to eliminate the problem organisms such as bacteria, yeast, moulds etc. along with reduction in the microbial counts to meet the desired standards. It reduces infection, which is prime concern when it comes to availing first-rate quality product. Sterilization also helps to achieve:

- Greater flavor retention.

- Extended product shelf life.

- Improved product appearance and texture.

- Prevent microbial contamination and degradation of the product.

ETO Sterilization

We are fully equipped with latest ETO Sterlization is a batch process in which products is stored in special chamber and are sterilized using Ethylene Oxide Gas. This is to confirm that the products are free from pests, insects and other harmful elements and the goods provided to the customers are best quality.

Steam Sterilization

Steam Sterilizer is a continuous process of sterilization of products with high pressure steam. This continuous steam sterilization process results in simultaneous reduction of microbiological load and the ample inactivation of enzymes in spices, herb & seeds as these raw materials are heavily contaminated with yeasts, moulds, enterobacteraceae and spore formers from the soil.

We provide ETO Sterilized, Steam Sterilized or Gamma Radiated material as per requirements.

In-House Laboratory Test

We have a well-equipped laboratory, with highly trained and efficient staff to provide best results. Our company organizes to send the Technical staff for Regular Training programs conducted by Spices Board and CFTRI to upgrade the knowledge and keep them updated with the current market requirements both domestic and international.

The laboratory conducts various tests to ascertain the presence of pests, microorganisms, pesticide residues in spices and other food products. Our entire R&D staff is well trained and they follow ASTA methods for analysis. Mainly four categories of tests/analysis are carried out in our lab.

Physical Analysis

- Appearance

- Colour

- Smell etc.

Chemical Analysis

- Moisture

- Volatile, Non-Volatile Ether Extract

- Curcumin

- Curcumin

- Color count

- Starch Percentage, etc.

- Ash

- Bulk Density etc.

Micro-Organism Analysis

- Salmonella

- E-coli

- SPC

- Yeast & Mould

- Coliforms etc.

Pesticide Residue Analysis

- Organochlorine Pesticide Analysis

- Organophosphate Pestcide Analysis

Packing

The packing is done as soon as the product is taken out of the fumigation / sterilization chamber to ensure the product’s hygiene from the atmospheric impurities. The packing of the products is either done by automatic Packing machine or through manually depending on the characteristics of the Products The packing material conforms to the statutory requirements for food products and is in accordance with the specifications of regulatory bodies such as the Indian Institute of Packaging, Mumbai & the Spices Board.

Automatic Packing machines

We have Hi-Tech Automatic Packing machines installed at our unit, which enables us to provide with best quality packing with minimal time consumption.

Metal Detector

Metal Detector is used to maintain the quality and hygiene norms of the product even at the final stages of production beside, speeding up operations. This phase of product processing and cleaning give surety that product do not contain any metal particle, which can be hazardous in nature.